We develop and manufacture measuring and testing devices according to your requirements / specifications and create the specification sheet on request. The following are some examples from a wide variety of spending areas, which may also be made public.

determine friction

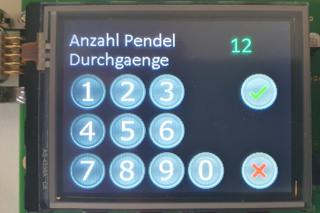

A pendulum impact tester is a testing machine (2023)

for determining the impact strength and impact work on standardised specimens. A pendulum impact tester generally consists of a pendulum hammer, which is mounted on a shaft with as little friction as possible, a frame to absorb the energy released and devices as specified in the various DIN standards. In order to determine the bearing friction, a device with a TFT touch display was developed, which measures the time e.g. for 100 full oscillations. To control the device, the laser light barrier is simulated with a frequency generator. The frequency and time are output. Internal resolution 100us by means of temperature-stable quartz.measurement

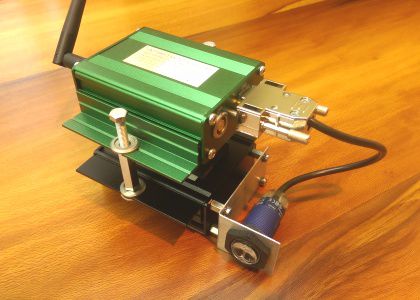

Torque measurement on rotating shaft (2016)

This package, consisting of our A12W measuring amplifier and our USV-01, was used on a shaft to determine the torque and speed. Strain gauges were applied to the shaft so that the torque could be recorded as a function of the speed 0..450 rpm. The measuring amplifier draws its power from the USV-01 battery pack. An optical light barrier was mounted at an angle on the USV so that an optical marker on a static part near the shaft could detect a pulse. The torque and speed are recorded in the process. The data is sent via WLAN to the measurement software, where it is displayed graphically and stored for further processing.

The reference resistance switch box RWU (2005)

was developed for a sensor manufacturer who wanted to connect up to 100 sensors sequentially to a DMM using different types of circuitry. It is possible to measure impressed currents via selectable load resistors 1kE / 100E, or voltages / resistances. Digital signals can also be connected to the sensor. A 19" rack is equipped with 10 relay cards and 10 multiplexer cards and can be expanded to 100 sensor inputs using a slave rack. The rack is controlled via an Ethernet interface with a defined protocol. The device takes over the complete handling of the relays to be switched and prevents short circuits and faulty switching.

Note counter testing device (1994)

For a company that specialises in coin and note validators, a test device was developed at the customer's request that was required for the adjustment of a note counter. The specific interface of the device could be connected directly to the tester via a ribbon cable and important parameters could be selected via a selector switch. The measured values were displayed on a commercially available built-in DVM.

Measuring torque for container closures (2004)

After filling foodstuffs into appropriate containers, random samples are taken to determine the torque of the closures. A distributor of these measuring devices wanted to offer a digital version in addition to its analogue measuring devices with drag indicator. To this end, electronics were developed that fit into the existing housing, including the matching sensor used. The device has an active 10Hz 2nd order Bessel filter to define the slew rate of the measurement signal and displays the positive / negative peak value. (CW / CCW)

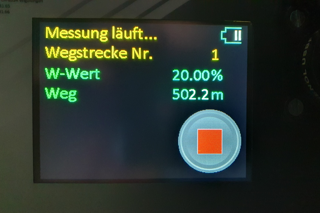

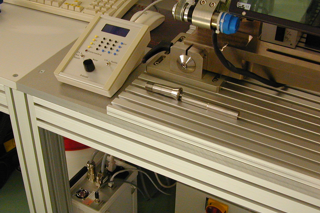

Measurement of road unevenness (1995)

In 2023, the project was redesigned with a 3.5" TFT display, internal memory for 3000 km for 20 distance measurements, and a USB interface. The Gonio measures road unevenness every 10 cm by means of a pulse on the middle wheel. The full-bridge measuring amplifier measures the deflection of the front wheel via a spring-loaded force transducer. In 1995, a Motorola 68K with battery-buffered static RAM and RS232C interface was used. At that time, the Gonio box could store approximately 20 km of measurement data. The processor was programmed in Assembler. The glue logic was built using Xilinx EPLDs, as the 68K did not contain any internal peripherals.

Motor and laser control (1998)

At the customer's request, a control system was developed for a HAASE laser and a small, high-torque Maxon DC motor. The aim was to weld small round components, e.g. lids. The control system was capable of 0...720° angle welding or cross-welding. The speed of the DC motor was variably adjustable, as were the angle degrees and the clockwise/anti-clockwise rotation of the motor. The control system took over the laser control and pulsed the laser exactly in the desired positions. A protective gas control system was also included, as was the option of using a linear table instead of the rotary table.

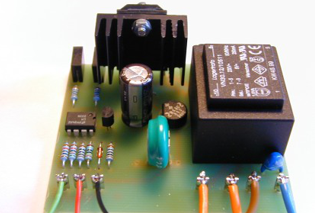

Relay box for swimming pool control (2000)

In private swimming pools, timers are used in the control system, e.g. for dosing liquids. As one of these timers was obsolete, the customer evaluated a new digital timer with a weekly programme. This contained no overrun in the event of a mains voltage interruption and a 1.5VDC operating voltage and alarm output. The box contained the power supply from 240VAC and an optotriac with zero-crossing detection so that inductive loads could also be switched safely. The module was installed in a housing for switch cabinet construction and was fitted with a fuse and LED. The integrated rechargeable battery ensured that the timer continued to run for 4-5 days in the event of a power failure.

Data logger for use in a transport system (1996)

In order to draw conclusions about the tensile forces in a transport system, a data logger was developed that stored the measured values of the force sensor every 600 Hz in a battery-buffered SRAM. The measurement data could then be read out using a Windows APP via RS232C and saved as a split EXCEL file for further processing.

PH / redox / conductivity measuring device (1995)

Redesign of the diploma thesis written in 1994.The device regulates the aquarium temperature using a glass PT100, which can be fitted with up to 3 temperature modules. Temperature modules can be fitted, which are used to calculate the average value depending on the number. The PH measurement in the range of PH 1-13 regulates the CO2 solenoid valve. If the CO2 is dosed via a reactor installed in the aquarium water, the gas dissolves in the water. This makes it slightly acidic, which is then determined and regulated via the pH value. In addition to lowering the pH value, the advantages are a lush plant life, provided that the light source and the carbon hardness are suitable.